FIA Rollcage Test

Vertical Main Hoop

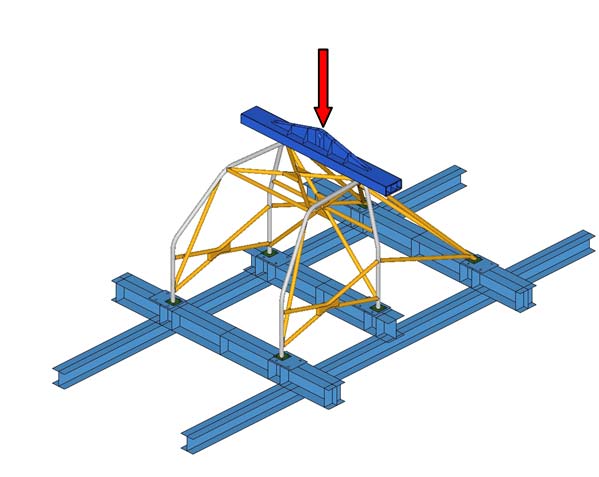

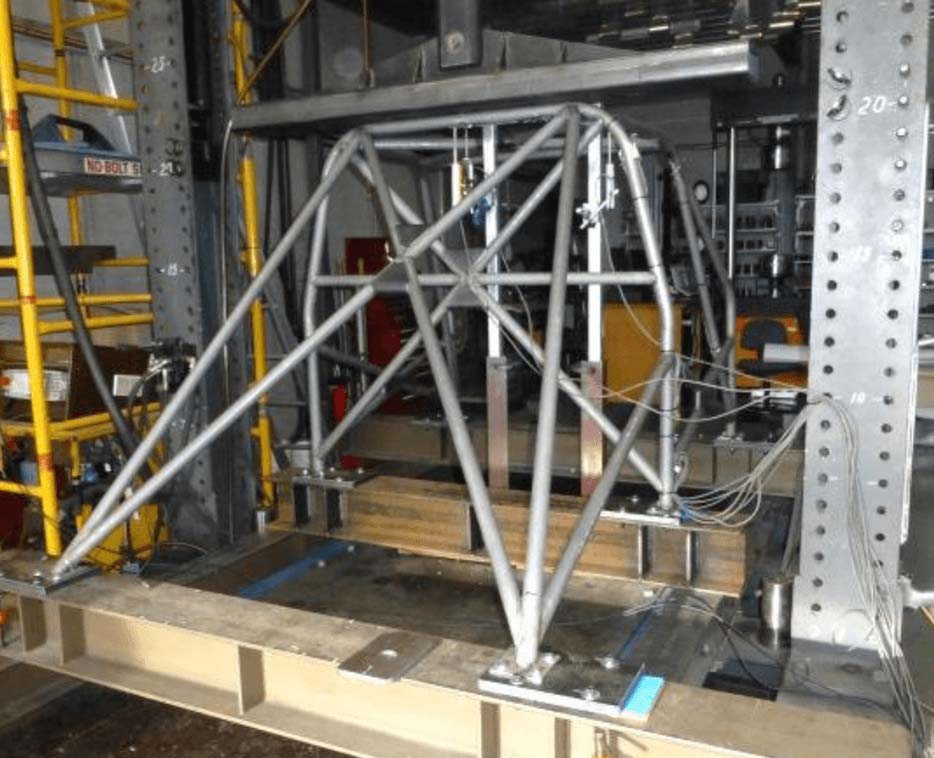

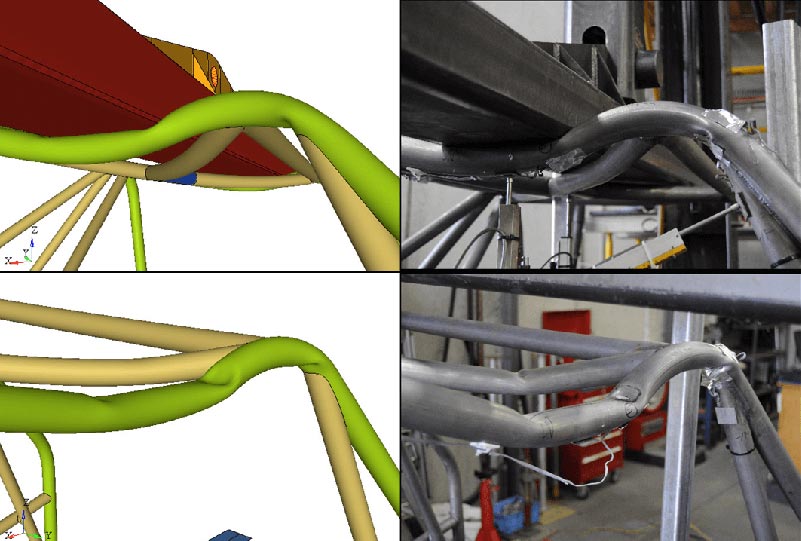

In order to demonstrate competence to the FIA, we were required to perform a physical test on a full size rollcage as per the FIA rollcage regulations, and then replicate the test using FEA.

We designed a mild steel rollcage to suit the test rig, which was loosely based around a medium sized vehicle weighing approximately 1200kg.

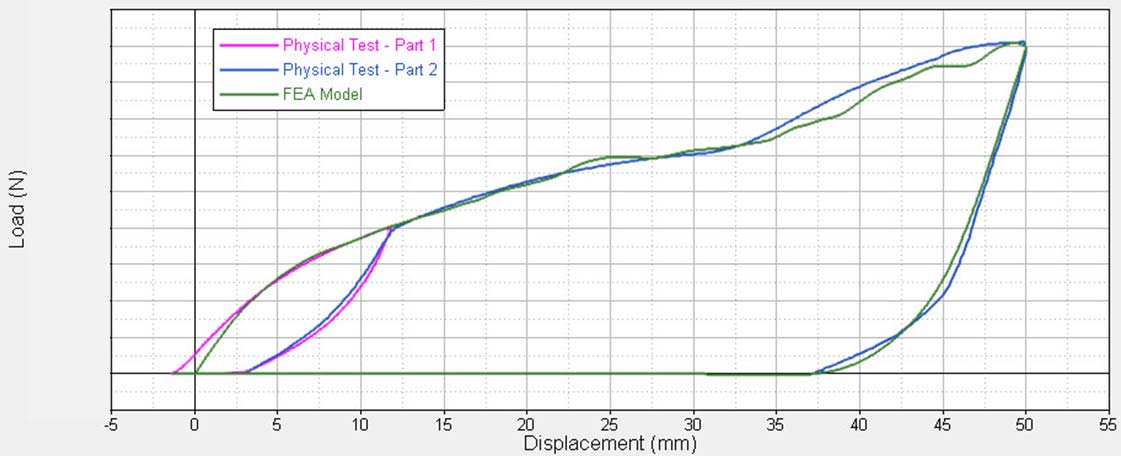

The required load on the main roll hoop is dependent on the weight of the vehicle, and in this case was around 100kN or 10T. Once we'd run the FIA load, we also ran another test on the main hoop where we applied the maximum allowable displacement of 50mm, which required a load well over 20T.

The rollcage was instrumented with multiple sensors and strain gauges so we could measure deflection and strain at various locations on the structure, and the load applied by the hydraulic cylinder was also recorded.

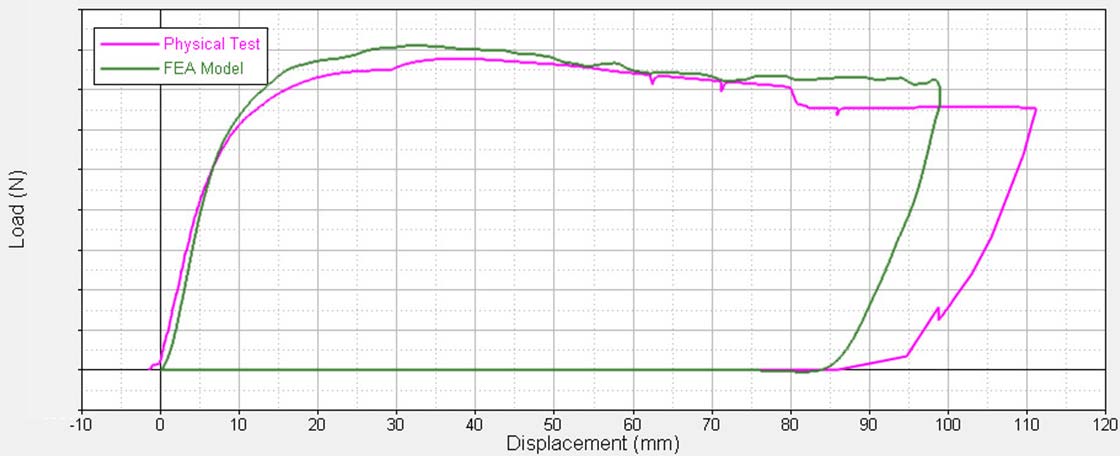

Results from the physical test are compared with the FEA results below, and as you can see, the correlation was very good.

Additional Testing

High Displacement Roof Test

In order to take full advantage of the opportunity for testing and gain as much understanding as possible, we performed an additional test on the full cage to see what happens at very high levels of displacement. We moved the stamp forward onto the unsupported roof section and loaded it to the travel limit of the test machine at around 120mm.

This level of loading and deflection is highly non linear and modelling this behaviour using FEA is quite complex, so we were looking to study and correlate our models as much as possible.

Again, the FEA results compared exceptionally well to the physical test:

Joint Tests

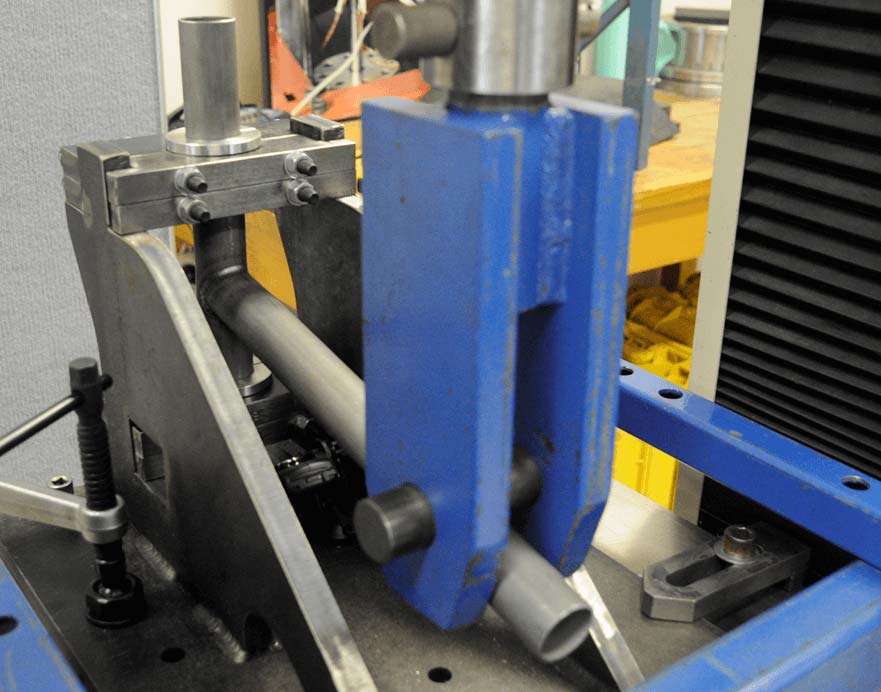

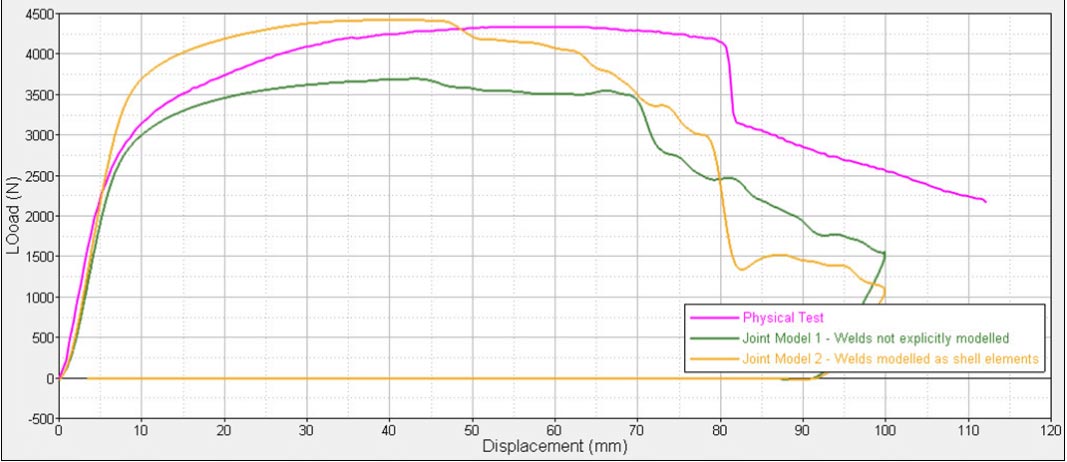

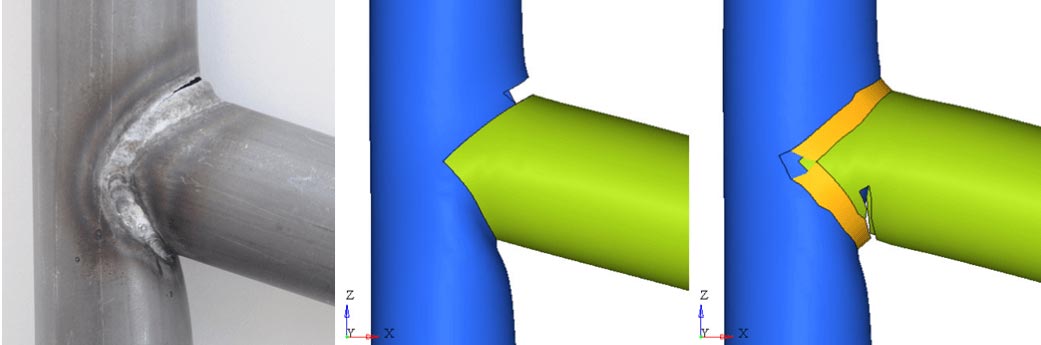

Detail T Piece Testing

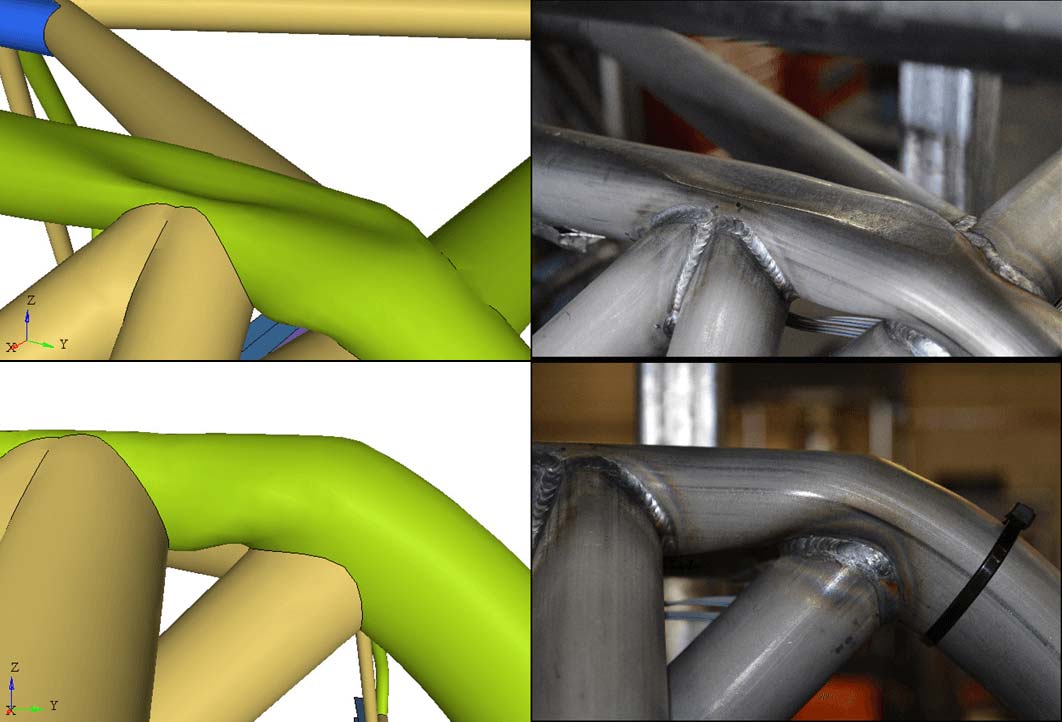

Another set of additional tests we did was to understand behaviour around welded joints. For these tests, we designed a set of fixtures to test a T piece, which can also be used for testing bolted rollcage joints to the FIA standards.

We tested various sizes of mild steel and chromoly T pieces and then fine tuned our FEA models of the welded regions to get good correlation. This was an invaluable part of the test schedule which gave us some critical insights into how to model failure of these welded joints both accurately and conservatively.

As you can see, there's been a lot of time and effort invested into developing and validating our rollcage modelling methods. This investment has given us a high degree of confidence in our simulations and will help us provide you with a rollcage design that achieves the ultimate balance between safety and performance.

If you would like to know more about our rollcage design and certification services, just drop us an email or give our office a call on +61 3 9029 3323 to have a chat to one of our engineers about what's possible.